Sustainability

Shoei Bijutsu takes the environmental challenge very seriously.

We created a management system based on the United Nations' 17 Sustainable Development Goals (SDGs) to encourage sustainable practices in the event industry that benefit both the environment and society.

We are constantly working to be your environmentally friendly,

trustworthy partner.

Recycle process chart flow until now

Waste generated during the event is either disposed of or burned to produce electricity.(GHG emissions)

How may we convert all of the waste generated after the event into raw materials?

Circular economy chart flow after the introduction for the "circular display system"

After some trial and error, we collaborated with our partner companies to create a "circular display system" that recycles and reuses waste materials and environmentally friendly components to create new raw materials.

We developed the "circular display system" through two initiatives.

To design the circular display system, we began with two initiatives: gaining FSC certification and building a system that allows us to reuse waste materials by introducing a 3D printer.

- O1FSC certification

-

Eco-friendly raw materials that support our planet and our customers.

Following the obtaining of the "ISO9001" and "ISO20121" certifications, we are the first company in our sector to obtain the FSC certification and develop an internal company environment in compliance with the needed international standards.

What is the FSC certification?

FSC is a system that allows wood from forests that have been recognized as socially, economically, and environmentally responsible, as well as the products derived from it, to be labeled and marketed as FSC-certified. Choosing and purchasing certificated products increases demand for certified forest resources, which leads to the expansion of well-managed forests. FSC certification is the most trusted forest certification in worldwide, with support from consumers, environmental organizations, and and many different countries.

- O2Reuse of raw materials with the 3D printer

-

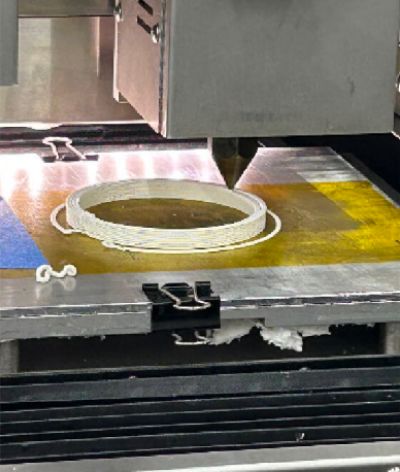

Reduce waste while expanding our possibilities for 3D modeling design features.

The 3D printer can be used to create objects and designs, however too intricate and not practical due to time constraints. Combining this new technology with our craft experience enabled us to expand our 3D modeling design capabilities.

-

Our Larger Size 3D printer

-

Because the 3D printer dimensions are W3m D3m H3m, it is technically possible to make a whole 9sqm booth.

-

With resilience,

we aspire to do better.

In order to achieve our ultimate goal of a sustainable event industry, we are constantly conducting trail tests to determine which material is more sustainable for which product, improving our upcycle process and exploring new design and implementation possibilities.